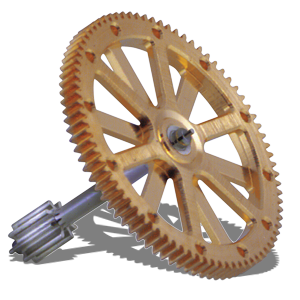

GEARTRAINS

Manufacturer of watch geartrains

MANUFACTURING OF WATCHMAKING GEARTRAINS

AFFOLTER specializes in watchmaking geartrains, offering a limited range of products but unbeatable expertise. From single discs to more complex discs, from functional geartrains to geartrains bearing the Geneva Seal, and from small batches to large-scale production runs, we put our 100 years of expertise to good use.

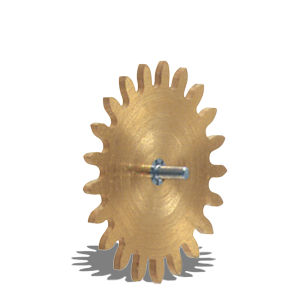

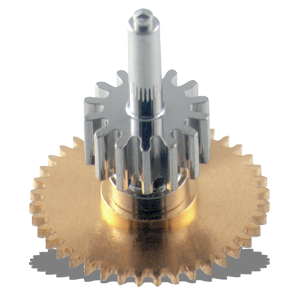

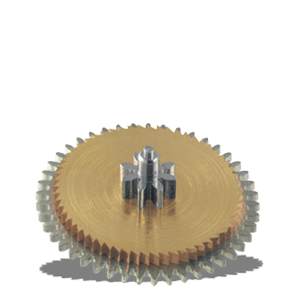

PINIONS

Starting with just a steel bar, our CNC and cam-type profile turning machines give shape to axles and pinions...Manufacture of turned pinions

Starting with just a steel bar, our CNC and cam-type profile turning machines give shape to axles and pinions.

We use our own high-performance AFFOLTER CNC cutting machines Our infrastructure is the key to producing top-quality burnishing and polishing finishes and includes heat treatment and washing processes.

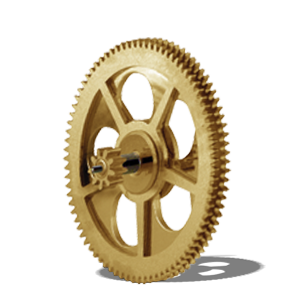

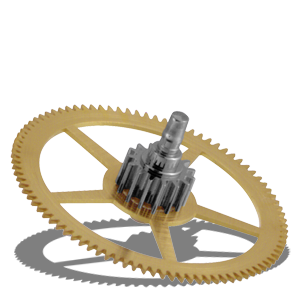

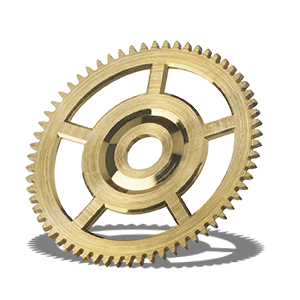

GEARS

From developing and manufacturing stamps to creating high-end surface finishes...Manufacture of stamped gears

From developing and manufacturing stamps to creating high-end surface finishes (circular graining, grooving, and chamfering), Affolter flawlessly executes every step of gear manufacturing. Our stable of innovative and exclusive “Affolter platform machines” can create quality components at industrial production rates. Gear hobbing is carried out on our AFFOLTER AF101 automated equipment.

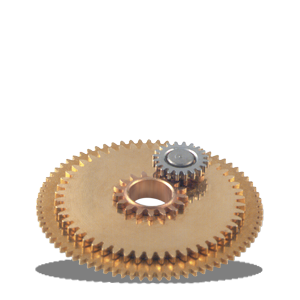

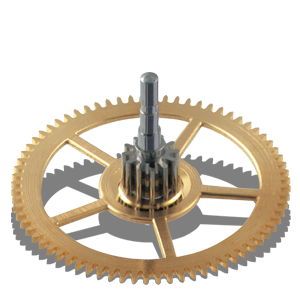

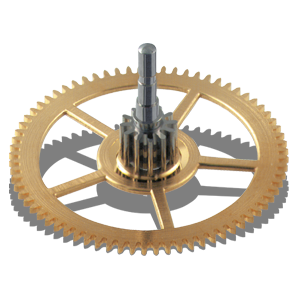

GEARTRAINS

Our assembly workshop is the place for riveting and driving axles, gears, and other components...MANUFACTURING OF WATCHMAKING GEARTRAINS

Our assembly workshop is the place for riveting and driving axles, gears, and other components, such as heart-pieces, in industrial processes.

Our expertise also extends to complex and delicate operations such as indenting and the assembly of friction wheels.

These discs and other watchmaking components make up your movement

Are you looking to produce small or large quantities

of watchmaking components?

of watchmaking components?